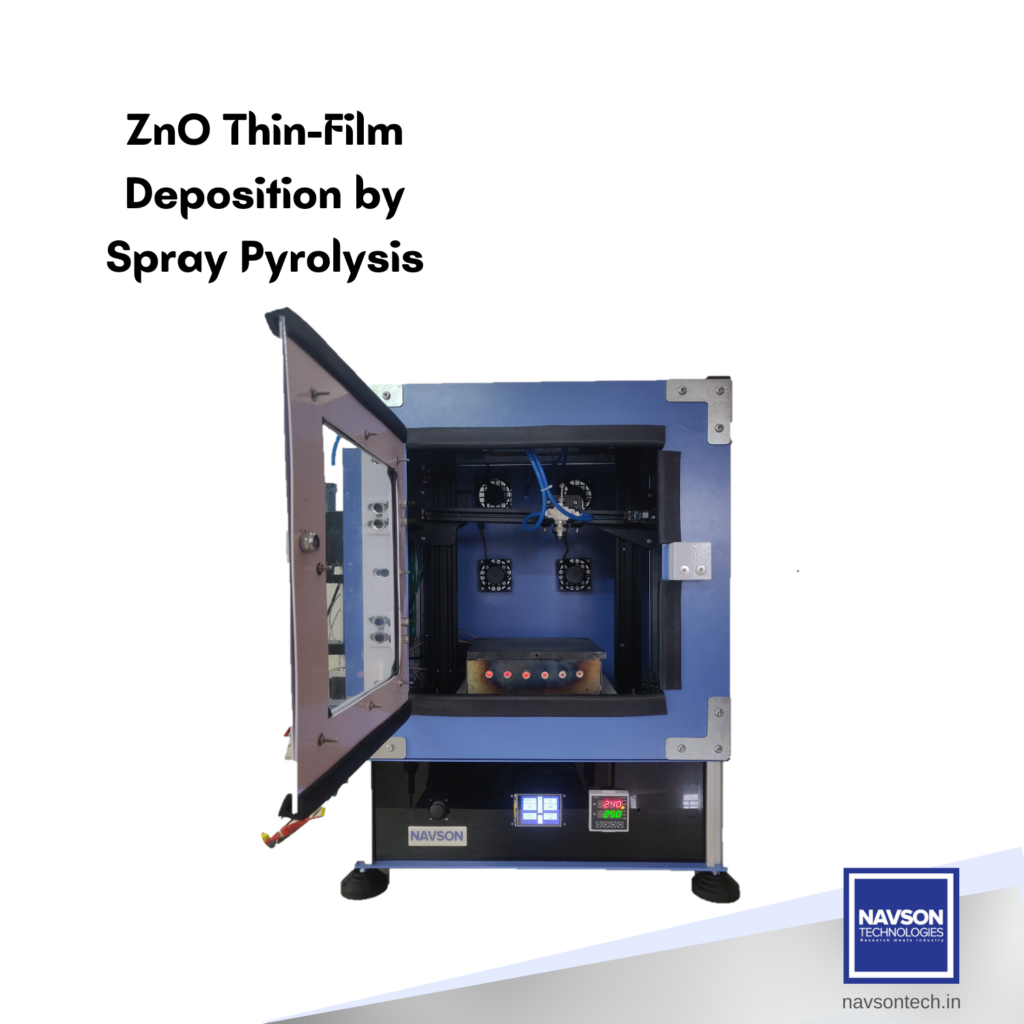

Spray pyrolysis is a processing technique which is used to prepare thin films and thick films, ceramic coatings, and powders. It has many advantages, such as inexpensive and simple experimental setup, easy control of chemical specimens, reproducibility, and uniform and large area coating. More about spray pyrolysis ZnO thin films…

Spray Pyrolysis Vs Vacuum Based Deposition

Metal oxide semiconductors like ZnO offer numerous advantages over competing technologies (e.g., organics, amorphous silicon) like high optical transparency, mechanical flexibility, processing versatility, etc. ZnO semiconductors are usually processed by vacuum-based techniques such as molecular beam epitaxy (MBE), chemical vapor deposition, ion-assisted deposition and pulsed laser deposition. However, vacuum-based deposition techniques have high manufacturing cost and their incompatibility with large area deposition.

Spray Pyrolysis ZnO

When ZnOis deposited by spray pyrolysis, it has good quality smooth films at temperatures above 300 °C and the crystallite size of it increases with temperature from 7.5 to 32 nm within the temperature range between 200 − 500 °C.

The FWHM values of spray pyrolysis prepared ZnO (59, 67 and 123 meV for 500 °C, 400 °C and 300 °C respectively) are comparably lower than the values reported by heteroepitaxial grown (∼ 117 meV), RF magnetron sputtered ZnO film (∼ 75 meV) and bulk ZnO (∼ 115 meV).

Excellent Operating Characteristics

These ZnO Thin-Film Transistors exhibit excellent operating characteristics with a maximum electron mobility of 25 cm2 V−1 s−1 and current on/off ratio on the order of 106. ZnO films grown at substrate temperatures in the range of 400–500 °C exhibit the highest electron mobilities with maximum average values in the range 20–25 cm2 V−1 s−1.