Perovskite Solar Cells: Achieving New Heights with Precise Spin Coating Techniques

As I wandered through the vibrant corridors of the Indian Institute of Science, the energy was palpable. Ms. Bhumika Sharma, a PhD research scholar whose name is becoming synonymous with innovation in solar energy, was kind enough to share her journey with me. “It’s not just about the technology; it’s about the promise of a brighter future,” she remarked, her eyes alight with the reflection of the sun that fuels her work on precise spin coating techniques.

In the realm of solar energy research, where the quest for sustainable solutions is relentless, perovskite solar cells are emerging as beacons of hope for mankind. These materials, akin to the chameleons of the material world, boast an extraordinary talent for capturing sunlight and converting it into electricity. Yet, harnessing their full potential is akin to conducting a symphony; each element must be in perfect harmony, especially during the delicate dance of the coating stage.

As I witnessed, the experiment that unfolded within the walls of IISc under the watchful eye of Dr. Sushobhan Avasthi was nothing short of alchemy. Amidst the hum of spinning machines and the sharp tang of chemicals, the team meticulously layered the perovskites, each application a step closer to an energy revolution. “Precision is key,” Dr. Avasthi explained. “Like painting a masterpiece, every stroke matters.”

This breakthrough in perovskite-based solar cells could very well pave the way to a world where our homes are not just shelters, but powerhouses of clean energy. So if you can imagine skylights that do more than offer a view of the heavens — rooftops that can harness its power, and every surface of a home a source of sustainable energy — our scientists can do it.

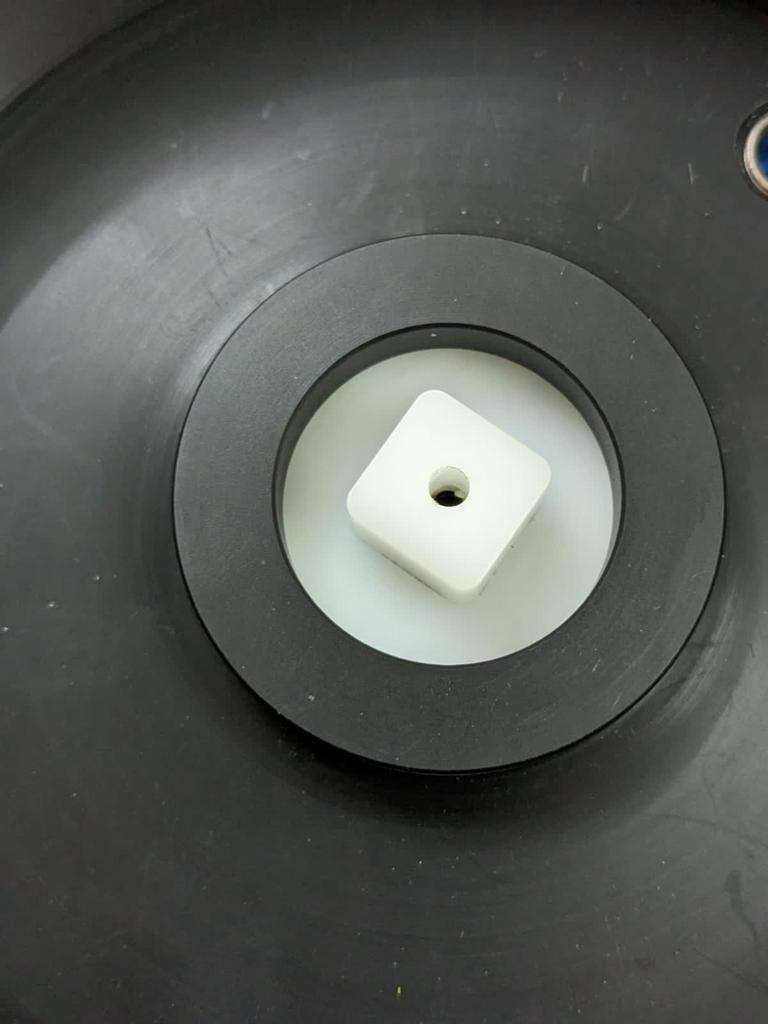

Perovskite Solar Cell Coating Experiment with Spin Coater NT12000V1 | Indian Institute of Science

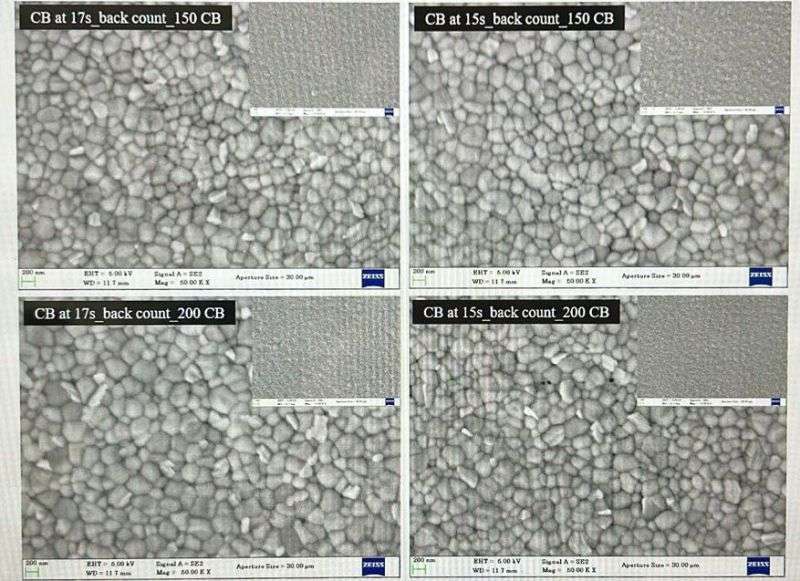

The study employed intricate methods for applying coatings, involving both spin coating and thermal evaporation within regulated settings. The objective was to achieve a film thickness of 450nm on glass and ITO-coated glass substrates, and the results showed a commendable precision with thicknesses ranging from 430nm to 480nm.

The spinning process was calibrated to 6000 revolutions per minute, with a 40-second duration and a 5-second ramp-up time. Additionally, the application of UV light was used to improve the film’s ability to be wetted, which is crucial for attaining uniformity and comprehensive coverage. The overarching goal of this research is to enhance the efficiency of Perovskite-based solar cells, highlighting the essential nature of these coating processes in reaching the anticipated level of cell performance.

Are you on the quest to push the boundaries of perovskite solar cell technology?

Discover the NT12000V1, a spin coater designed with the researcher’s need for meticulous precision in mind. Dive into the capabilities of this tool and see how it can be the ally you need to forge new paths in the development of cutting-edge perovskite solar cells.

By interns at Navson Technologies. Reposted on LinkedIn.