Spin coating is a technique which uses centrifugal force to spread uniform thin films of interest on a flat solid surface. The spin coating technique is extensively utilized in microfabrication of useful oxide layers on glass or single crystal substrates using sol-gel precursors. This helps to create uniform thin films with nanoscale thicknesses. In other words, spin coating is ubiquitous in semiconductor and nanotechnology R & D and industry. So what is a spin coater syringe pump?

Syringe Pump In Spin Coater

Dispensing of solution is a very important process in spin coating. There are many disadvantages in manual dispensing as specific timing and dispensing rate is required for precise coating. Also, the time interval is too short to perform manually between multiple dispensations. These issues can be rectified by using syringe pumps.

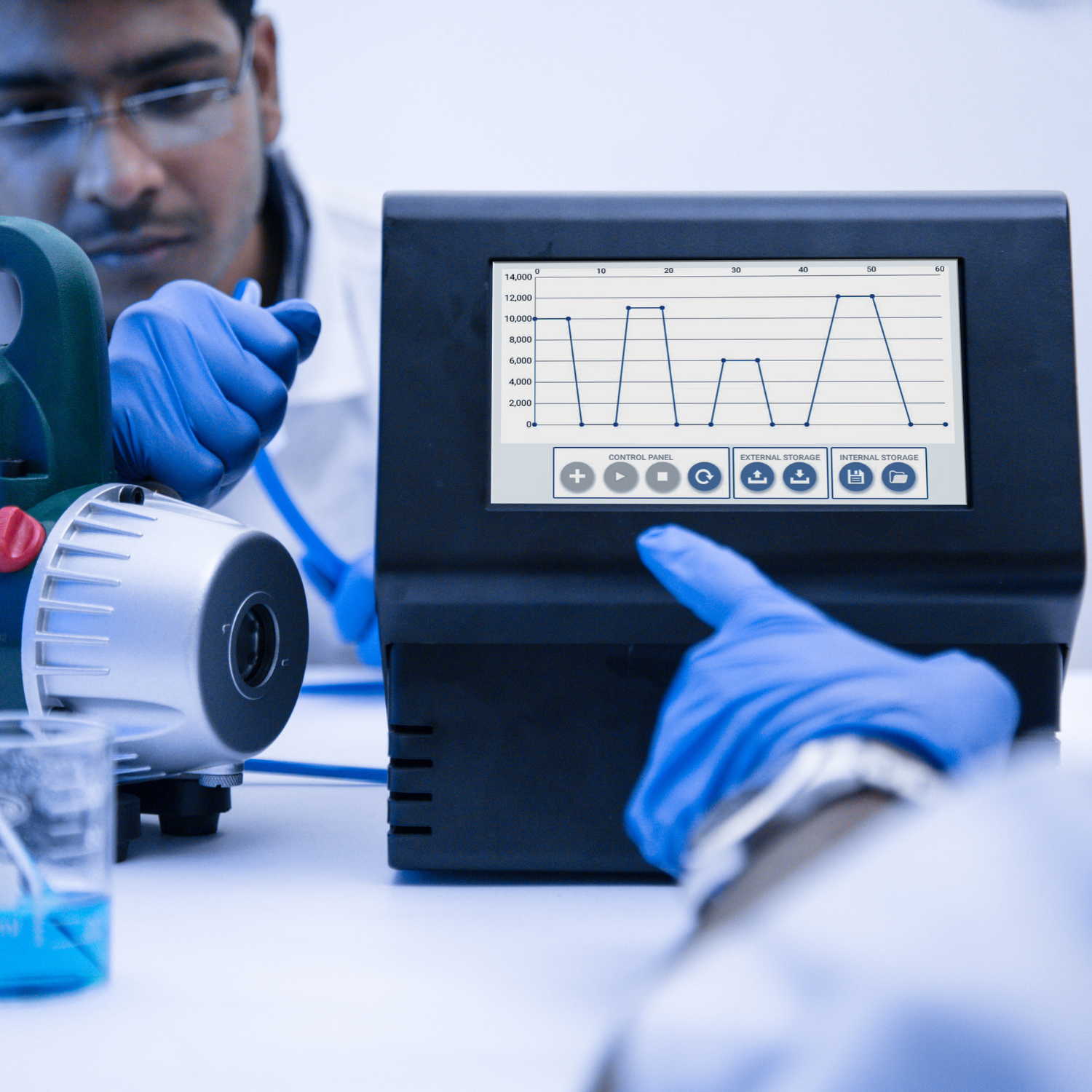

A syringe pump in spin coater is a liquid processing equipment used in sensitive research and industrial environments to dispense the liquid of interest. Syringe pump applications can range from chemical and research biology to food processing and industrial micro-dispensing needs. It consists of a motor, its driver and also has a reciprocating screw and nut. The nut connects this driver to the piston of the syringe containing the liquid. This mechanism helps to regulate the amount of liquid injected to achieve an accurate and smooth supply.

Advantages: Spin Coater Syringe Pump

- Rates of dispense and timing of the dispense can be controlled in the syringe pump to deliver extremely high degrees of accuracy which is not possible with manual solution dispensing.

- It is highly effective when dealing with dispensing multiple solutions in spin coaters.

- Multilayered structures that require alternating multilayer coatings can be fabricated rapidly and reproducibly when using a syringe pump.

- In situations where it is necessary to wash the substrate with a solvent before dispensing the solution to improve wetting on the substrate, a syringe pump can be used to time the dispensing of the solution so that it occurs just as the solvent is evaporating can dramatically improve the wetting.

- It can also help to improve homogeneity, repeatability and film-quality on wafers, reduce chemical waste and minimize direct handling of chemicals.

Syringe Pump Spin Coater Cost

Contact us for Navson Spin Coaters with syringe pump and accessories like connection adapter, disposable syringes, PTFE tubing, and needles.

BY V.R.NIVEDHA SHALINI